| English | Select | |

| 한국어 | Select | |

| Русский | Select |

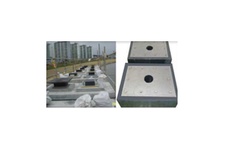

Bearing Pad for Supporting Bridge

It connects the top and bottom structure of bridge and overpass. It is the product with superior weather resistance and dynamic characteristic, which is designed to deliver the load applied to the top bottom structure effectively, absorb expansion or contraction of top structure and relevant change top and bottom structures and enable entire structure to maintain safety against thermal change, impact and movement.

Structure of bearing pad

Function and characteristic of bearing pad

- It is good for wide skew bridge and curve bridge.

- It is free from the movement caused by shear transformation and

elastic transformation.

- It can support the load of 8~3,000 Ton depending on load contact area and

material strength.

- Its maintenance and construction are convenient.

- It is economic.

Structure of bearing pad

1. It is installed in the interval between top structure of bridge and its foundation. It support top structure, grants degree of freedom,

absorbs expansion depending on the change of temperature and load and relieves earthquake vibration.

2. Various designs are available depending on contact area, design method and rubber material and it can cope with expansion and

change so it can be widely applied to skew bridge and curve bridge as well as horizontal bridge.

Durability of bearing pad

1. Bearing pad shall stand against dynamic changes of top plate of bridge (horizontal movement, load change and expansion)

and support vertical load of top plate.

2. Bearing pad shall secure sufficient durability for long-term dynamic change and minimize shape change for long-term use.

3. Bearing pad shall secure outstanding durability against ozone, UV lay, heat and basic because it is exposed for a long time.

4. The characteristic of rubber decides durability and lifespan of bearing pad so it shall be manufactured on the basis of abundant experience

in the process from prime material selection to mixture and vulcanization, It is important to possess the testing machine with precise

function and perform continual quality control for verification.

Type of bearing pad

1. Bearing pad for supporting bridge, KS product ( KS F 4420)

2. Lead rubber bearing pad (LRB) : Lead core is inserted in the center of bearing pad. It secures stability against movement by absorbing

large horizontal energy with the natural yield to long-term load.

Classification by function

1. Fixed side restraints bearing.

2. One-way

TF: Transversely fixed side restraints bearing

LF: Longitudinally fixed side restraints bearing

3. FR: Free sliding in all direction bearing